- Sectors

- Aerospace & Defense

- Big science

- Fintech

- Insights

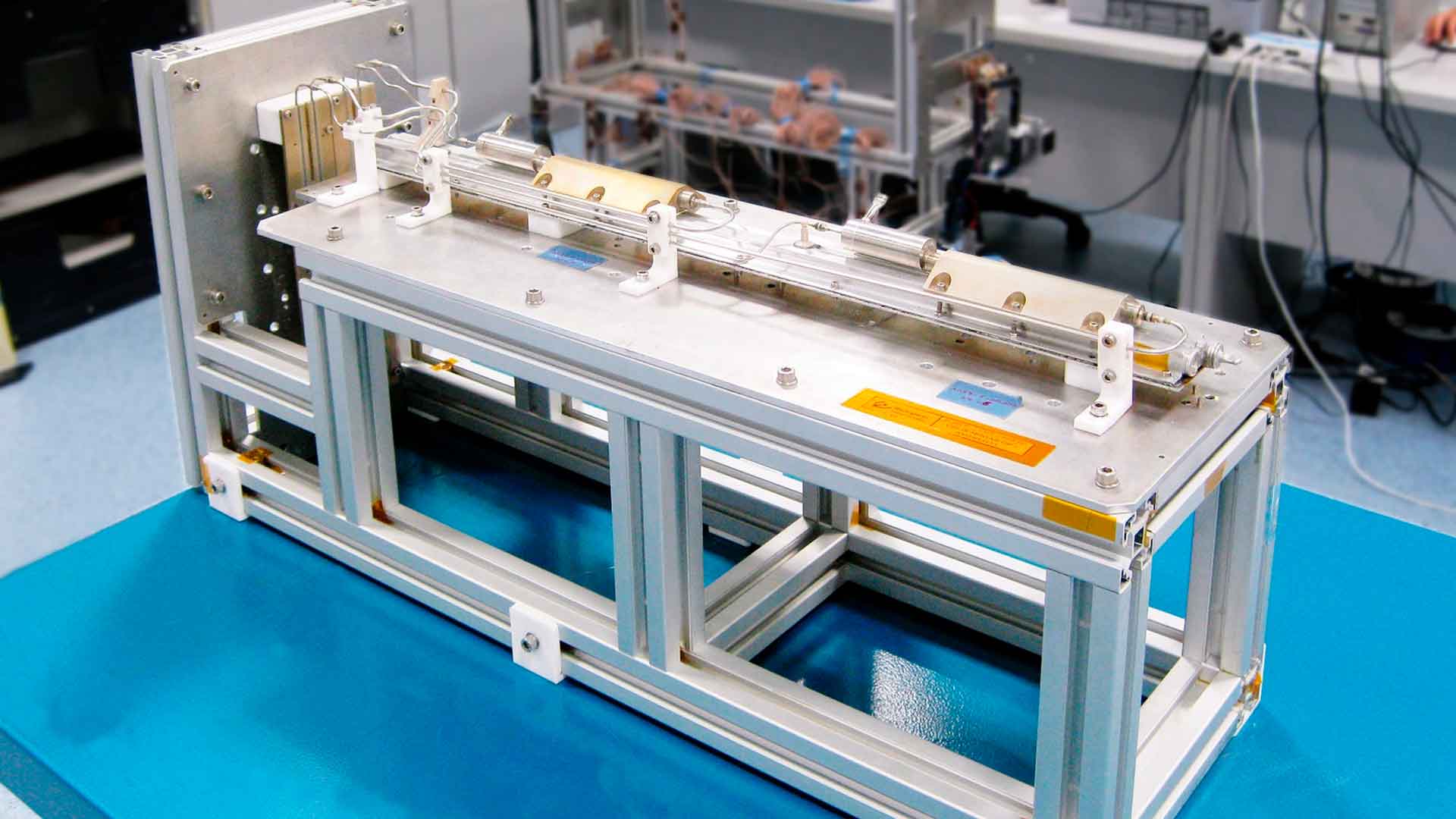

ARQUIMEA has capabilities for the design and manufacture of a high effective two-phase heat transfer passive device: the Loop Heat Pipes. Our Loop Heat Pipes operate under adverse orientation in ground and are the core of our Deployable radiators.

A Loop Heat Pipe is a two phase (liquid-vapor) flow heat transfer device that utilizes evaporation and condensation of a working fluid to transfer heat and the capillary forces developed in the fine porous wicks to circulate the fluid. They are often used in situations where conventional heat pipes would be ineffective, such as when mechanical decoupling is required.

ARQUIMEA’s Loop Heat Pipes are provided fully customized and could be provided with wicks made of Aluminum Alloy, Nickel, Titanium or Stainless Steel. They have a transferred heat power of up to 1Kw, a temperature operation range from 140k to 400k, a capillary pressure of 4*104Pa (ammonia) and a thermal resistance from 0,005. The working fluids are ammonia, propylene, ethane and Freon R134a. They can reach 10 m length with evaporators from 40mm to 400 mm length and have a lifetime of more than 15 years.

Our Loop Heat Pipes are an essential part of our Deployable radiators, offer the capability to smoothly transport heat and the proper operation for different heat loads.

It also ensures the stable temperature operation and the capability to control the temperature set-point thanks to a Pressure Regulation Valve. They are non-sensible to gravitational forces, allowing a complete thermal subsystem ground testing, lack of noise, reasonable mass and clean interfaces.

We have worked on large projects with the main space agencies and satellite operating companies in different international missions, such as ExoMars, Intelsat 19, Intelsat 20, Star One C4, Astro-H.

Contact us, set us a challenge and discover everything we can offer you.