- Sectors

- Aerospace & Defense

- Big science

- Biotechnology

- Fintech

- Insights

The work is framed within the EMA4FLIGHT and VALEMA projects. Both projects are financed with funds from the European Union´s Horizon 2022 research and innovation program under subsidization agreements No. 738042 and 755615.

The EMA4FLIGHT and VALEMA Projects follow two main objectives:

The development of Electro-Mechanical Actuation systems for aircrafts will help to achieve the objectives set by ACARE for the aviation industry as they will reduce the weight of the aircrafts enabling a consumption reduction. The designed sub-systems are improved by electric motor and ballscrew innovative architecture, advanced control strategies and smart safety, diagnostic and maintenance functions.

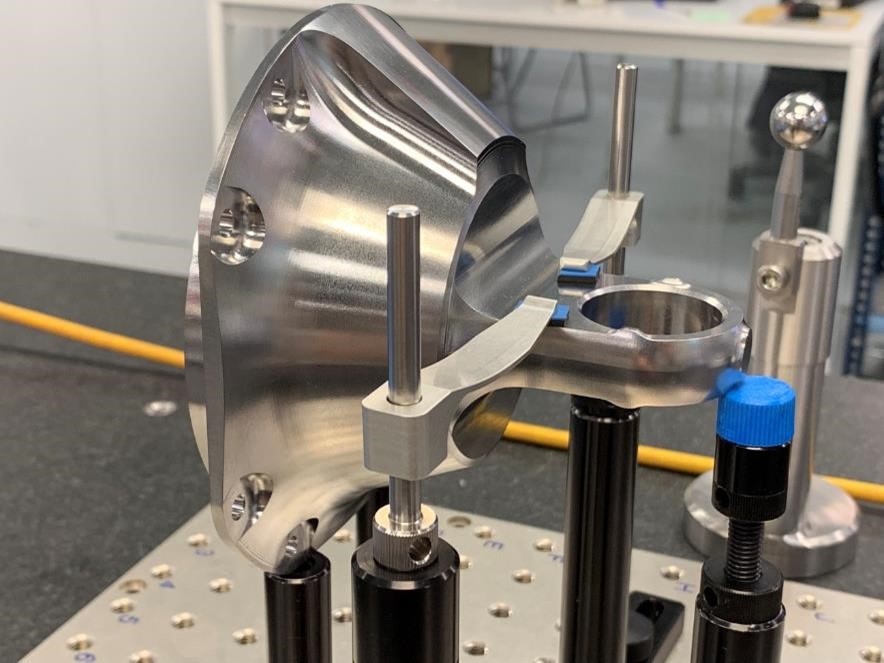

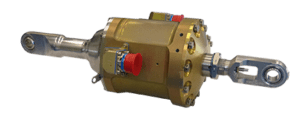

ARQUIMEA’s participation in the projects focuses on the industrialization, manufacturing and verification of the mechanical components that make up 9 EMA units for the Aileron System, 13 EMA units for the Spoiler System, 11 Servo-Hydraulic Actuator (SHA) units for the Aileron System and 6 Roll Feel Units, a total of 1274 parts from 84 different references.

The main activities involved in the projects are high-precision machining to very tight dimensional and geometric tolerances, plastic deformation, heat treatments, surface treatments and coatings and non-destructive testing. The materials involved are first level aeronautical alloys such as Aluminum 7000 series, Precipitation Hardening 15-5 and Nickel Aluminum Bronze C63020.

The system has been developed and integrated by CESA/HÉROUX-DEVTEK, manufactured by RAMEM, manufacturing company part of ARQUIMEA since 2020 and is complemented by the motors and ballscrews developed by UMBRA.