- Sectors

- Aerospace & Defense

- Big science

- Fintech

- Insights

RE2POS stands for PREcision-based drive mechanisms for high PREcision and energy efficient POSITIONING devices. It is an R&D project carried out within the framework of the European Union’s Horizon2020 research and innovation program by a consortium formed by ARQUIMEA and the Italian company Phi Drive. PRE2POS focused on the validation of new rotary actuators using an innovative motor that exploits the micrometric deformation displacement of piezoelectric stacks to achieve infinite rotary or linear motion. The project also included the analysis and definition of the next steps towards industrialization and commercialization of the resulting product.

The ultimate goal is to include rotary actuators in key equipment and mechanisms used in spacecraft, such as solar panel array drive mechanisms, antenna pointing mechanisms or deployment mechanisms such as arms and masts, where end users are constantly looking for high precision, low weight, energy efficiency and low manufacturing costs.

The project was successfully completed in 2020 with formal approval from the European Commission.

Currently, the main commercial actions have already started and are oriented to new and small satellite platforms still under development that might be more interested in using this disruptive technology to become more competitive.hh

The project team had to develop a new state-of-the-art solution with the objective of improving the technical and economic performance of equivalent products currently available.

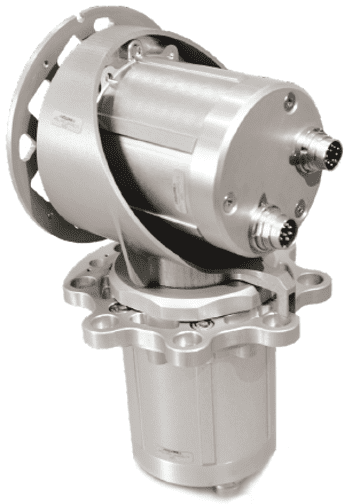

A complete rotary actuator for the space market was developed and validated taking into account the sizing of the drive motor and the optimization of its performance.

In addition, a smart design was developed to ensure a cost-effective integration of the Pre2Pos motor components into ARQUIMEA‘s custom gimbal design.

Finally, as the idea was to use this solution in future small satellite platforms that require off-the-shelf products with a short lead time, the gimbal had to be a standard product, affordable in cost and with a short lead time.

The ARQUIMEA gimbal activated by means of the Phi Drive motor device is a two-axis positioner whose function is to precisely steer a load. The gimbal consists of two motors driven by piezoelectric batteries with electrical redundancy. It includes two degrees of freedom: rotation in the roll and yaw axes.

The system design shows moderate torque capabilities (torque to mass ratio is +95% compared to existing solutions), providing system simplification with very high accuracy and resolution and very low user clearance avoiding the use of additional gearboxes.

ARQUIMEA’s gimbal is based on the coordinated drive of several separate two-stage piezoelectric stacks operating with a certain phase shift. The system offers individual rotational steps as small as 0.002° with moderate speed.

By adapting the operating parameters, the output torque or rotational speed can be adjusted to the necessary technical requirements. The position control can also be adapted to different needs, as this gimbal controls the position by means of an optical encoder.

ARQUIMEA and Phi Drive developed the complete solution for the release and deployment of the antennas, the scientific instruments and the pointing and positioning of the reflectors.

A total of three EQM models of the system were manufactured to validate the solution. The acceptance test campaign of the EQM models was conducted and concluded by the end of 2019. This solution was successfully tested taking into account the requirements and the operational and design conditions of space applications.

ARQUIMEA’s gimbal, together with the Phi Drive motor, proved to be the right solution for the target applications on small satellites.